Now that the Canoe up-grades and Dip net projects are done for the year, i’m starting on a Glass fly rod and Kevlar rod tube.

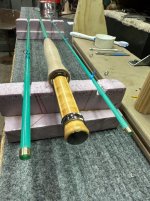

I recently picked up this 7’6” 3wt. Fiberglass blank and am excited to have this project. Ive made numerous Rod tubes so that’s the easy part.

First thing was to fit the reel seat to the butt. It was larger than the bore in the reel seat so i cut 4 inches off the blank and made a carbon stent to join the seat to the rod. The short brown piece was taken from out in the middle of the brown rod section in the 2nd pic, and all was assembled with 105/207.

Now that im waiting for the remaining fly rod components i started on the Rod tube. Most of the ones i’ve made were carbon fiber but im using Kevlar on this one. Starting with a T12 bulb protector i roll wrapped it with some 2oz glass tape and rasp/sanded it smooth, before slipping the Kevlar sleeve in place.

Knowing the difficulty of finishing Kevlar neatly, i out thunkit this time by bunching the sleeve at the top and turning the fabric in on the bottom. The Machined ends will go over or into the finished tube and give a nice neat look. I never sand my Carbon tubes, preferring the textured finish which this one will have as well.

I’ll go over it again this afternoon with some more epoxy and move on to Machining the end fittings tomorrow.

I’m using brass for these versus the Aluminum i typically use on Carbon tubes.

I recently picked up this 7’6” 3wt. Fiberglass blank and am excited to have this project. Ive made numerous Rod tubes so that’s the easy part.

First thing was to fit the reel seat to the butt. It was larger than the bore in the reel seat so i cut 4 inches off the blank and made a carbon stent to join the seat to the rod. The short brown piece was taken from out in the middle of the brown rod section in the 2nd pic, and all was assembled with 105/207.

Now that im waiting for the remaining fly rod components i started on the Rod tube. Most of the ones i’ve made were carbon fiber but im using Kevlar on this one. Starting with a T12 bulb protector i roll wrapped it with some 2oz glass tape and rasp/sanded it smooth, before slipping the Kevlar sleeve in place.

Knowing the difficulty of finishing Kevlar neatly, i out thunkit this time by bunching the sleeve at the top and turning the fabric in on the bottom. The Machined ends will go over or into the finished tube and give a nice neat look. I never sand my Carbon tubes, preferring the textured finish which this one will have as well.

I’ll go over it again this afternoon with some more epoxy and move on to Machining the end fittings tomorrow.

I’m using brass for these versus the Aluminum i typically use on Carbon tubes.

Attachments

Last edited: