For those of you that may have missed it, here are the photos and a plot to show the single shear seat cleat test. It was tested to failure at over 300 lbs load. The Cabosil thickened epoxy joint held fast, the failure was limited to the mahogany itself.

I specifically applied the load at a similar location to where a seat frame would likely contact the cleat.

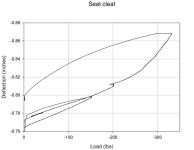

For those that need guidance to read the plot, the major axis is the applied load and the minor axis is the resulting deflection. Note that the delta deflection is all that matters, the starting point is an arbitrary value.

The load was applied initially from 2 lbs to 150 lbs, then cycled back to 2 lbs, so you see the small hysteresis loop.

Next, the load was increased from 2 lbs to 200lbs, you can see the resulting deflection as I dwelled at 200 lbs. This is actual yielding of the mahogany.

Finally, load was increased from 200 lbs to 325 lbs, and cycled back to 2 lbs, that's the large hysteresis loop.