If you have ever paddled with a ZRE Power Surge Flatwater blade, you know that it goes in the water with almost no splash and carries almost no air down with it. That’s because the tip has this fine, very gentle, extremely precise backwards curve that uses black magic and witchcraft to synchronize with the speed of the water, the angle of the paddle blade, and the changing angle of the shaft during the catch phase.

It’s astounding and wonderful!

If you have ever repaired a ZRE Power Surge blade, you’ll know it’s also a bear to maintain during the repair.

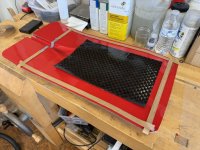

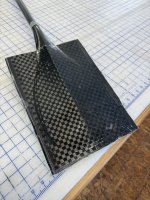

I have a couple of ZRE PS Mediums with broken tips and repaired one this evening. After removing loose delaminated carbon and prepping the blade, I used laminating epoxy to repair the snapped foam core and add two layers of 5 oz spread tow carbon, one on each side of the blade.

The key to getting that mystical curve *just right*?

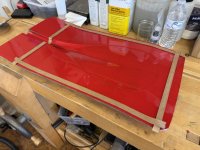

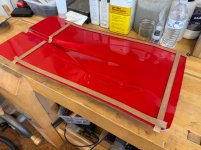

Steve Landick made a mold of the power face of a ZRE PS years ago and that curve is indelibly captured for blade repairs. He’s paddling down South for the month, so I snagged it from his shop.

Usually this would be vacuum bagged, but I realized that a fuse on my pump is blown after mixing the resin and I don’t have a spare! Bags of white rice will do in a pinch and compress the fabric sufficiently. It will have a little extra resin in it and might weigh half an ounce or so more than if it had been bagged.

When I do the other one, I’ll post new photos of the bagging process and the clean mold. I didn’t think to take photos and post about it until the repair was already on the mold.

It’s astounding and wonderful!

If you have ever repaired a ZRE Power Surge blade, you’ll know it’s also a bear to maintain during the repair.

I have a couple of ZRE PS Mediums with broken tips and repaired one this evening. After removing loose delaminated carbon and prepping the blade, I used laminating epoxy to repair the snapped foam core and add two layers of 5 oz spread tow carbon, one on each side of the blade.

The key to getting that mystical curve *just right*?

Steve Landick made a mold of the power face of a ZRE PS years ago and that curve is indelibly captured for blade repairs. He’s paddling down South for the month, so I snagged it from his shop.

Usually this would be vacuum bagged, but I realized that a fuse on my pump is blown after mixing the resin and I don’t have a spare! Bags of white rice will do in a pinch and compress the fabric sufficiently. It will have a little extra resin in it and might weigh half an ounce or so more than if it had been bagged.

When I do the other one, I’ll post new photos of the bagging process and the clean mold. I didn’t think to take photos and post about it until the repair was already on the mold.

Last edited: