Been working on another winter project for next season - a homemade camp chair. I stumbled on this Pinterest page called "Canoe Projects" and came across the source of inspiration...the Knudsen Bucksaw Chair! Anyone else seen these before?

Apparently it was designed by Dutch engineer Ole Gierløv Knudsen in 1962. The chair and an accompanying cot were created for a camping trip with his son. The original chairs from the 60s are apparently expensive collector's items today. You can see that the chair is held together by the tension of the windlass cord like a bucksaw. The whole thing collapses into a narrow stuff sac.

Certainly will never be as compact or lightweight as the modern Helinox Chairs that folks have been raving about, but I liked the concept. For a while I toyed with the idea of recreating the exact chair, using scrap canvas to sew the fabric and some hardwood for the frame components. But instead, I simplified the idea with whatever pre-fabricated scraps I had at home. All of the wood components were originally purchased (for other projects) at Home Depot, so they are pretty accessible. Here is what I came up with...

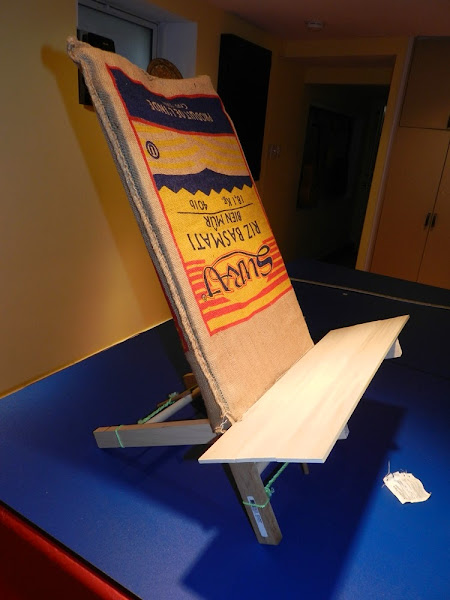

Little different that the original inspiration in that there are two windlass cords for the front and rear legs with a burlap sack for the backrest and wooden slats for a seat. But the concept of using tension similar to a bucksaw is the same.

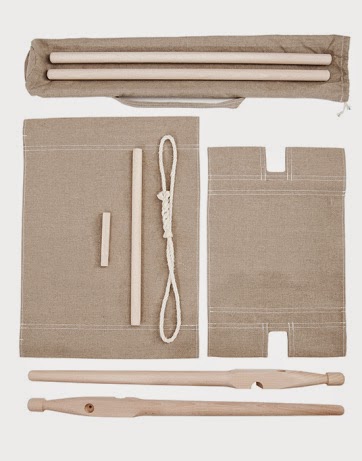

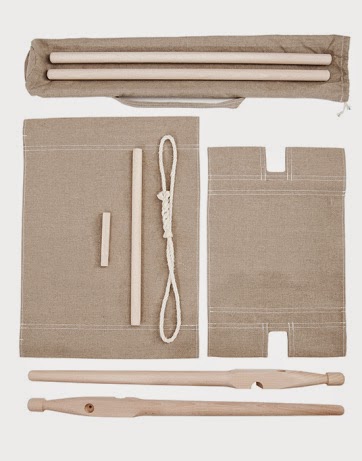

Here are the components laid out from top to bottom

• the backrest fabric is a 17" w x 26" l burlap rice sack. I suppose an old pillow case or large nylon stuff sack could work too.

• seat slats are 3 loose pieces of 1/4" x 2.5" w x 24" l poplar panels

• 2 seat legs made from a remnant of dressed 1x2x8 of maple (actual dimensions are 3/4" x 1.5"w x 22" l)

• 2 backrest legs made from the same maple stock ( 3/4" x 1.5"w x 30" l)

• 2 3/4" poplar dowels for the cross braces (long one = 13.5"; short one is 11-7/8ths")

• some cordage and 1/4 dowel sticks

Unlike the original Bucksaw chair which has the seat legs nestled into a carved space on the exterior of the backrest frame, I ended simply attaching 2 cut block of maple onto each long using some glue and screws. Took some trial and error, but eventually settled on on placing these blocks so that the space created between would be 7" from the leg bottom. Also, I ended deviating from the Knudsen's design by purposely flipping the legs so that these notches facing inward rather than outward. The following sequence of pics might explain this better.

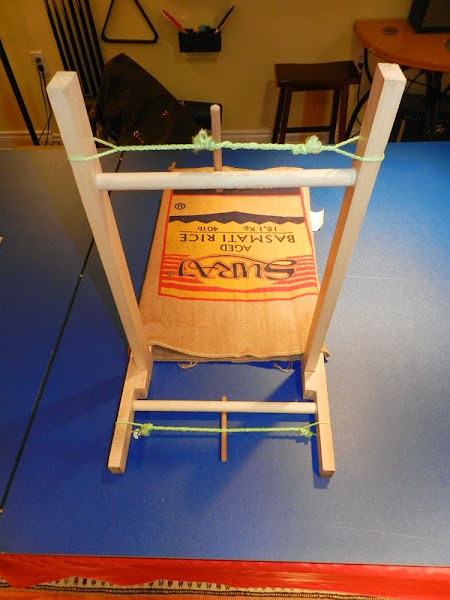

Here is the 1st step. Stick the long legs into the burlap sack with the "blocks" facing inward and tension with the cross piece and cord.

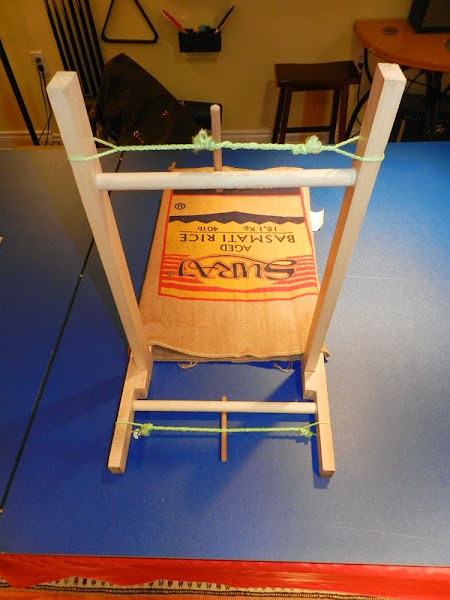

Then I place the other short legs into the support blocks and tension with the second dowel and cord. The tension created by the inner structure has a sort of friction lock at this stage. This is the view of the back of the chair...

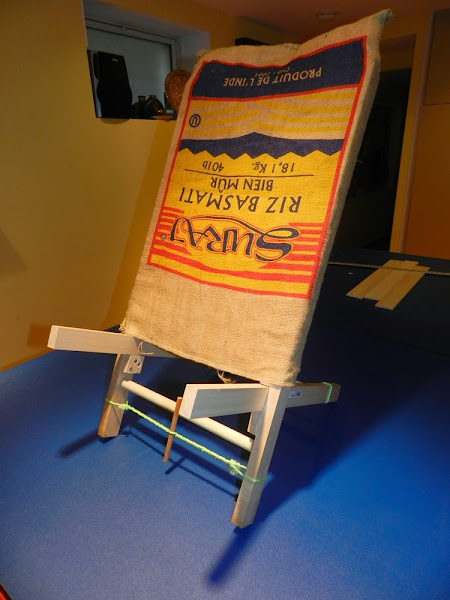

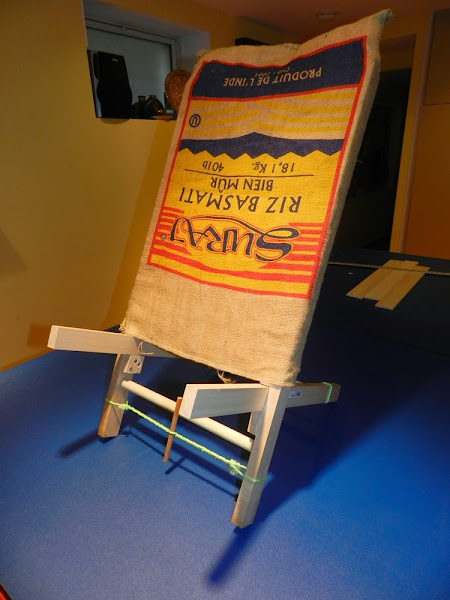

Flip up and adjust how far back you want the chair to lean. This is accomplished by slightly squeezing the shorter seat legs towards each other near the block supports. The legs can then slide through the blocks and when you let go, they snap outwards again for an instant friction lock.

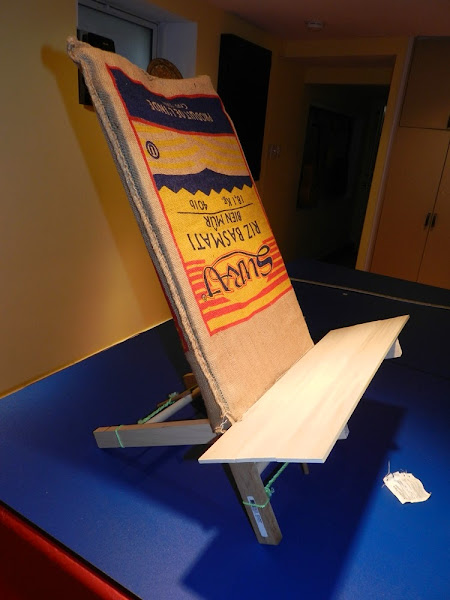

I had originally thought of using fabric for the seat again, but found that because of the width of the burlap back rest, something would need to be customized. I later got the inspiration from my 6 year old son who was playing with the 1/4" poplar boards building a sort of racetrack. I snagged 3 of his boards and found that they could easily rest, edge on edge on the projecting maple supports. Works well enought as a comfortable seat.

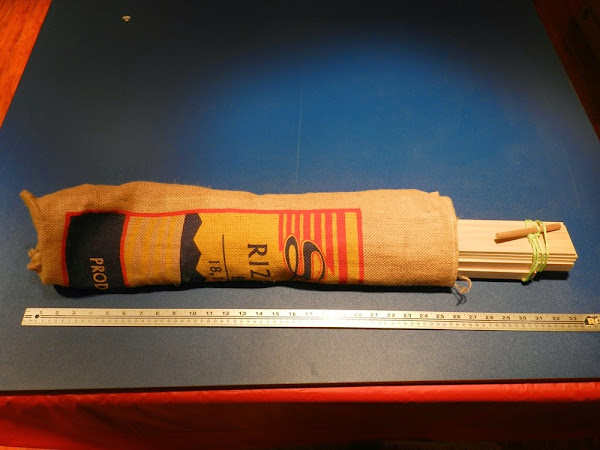

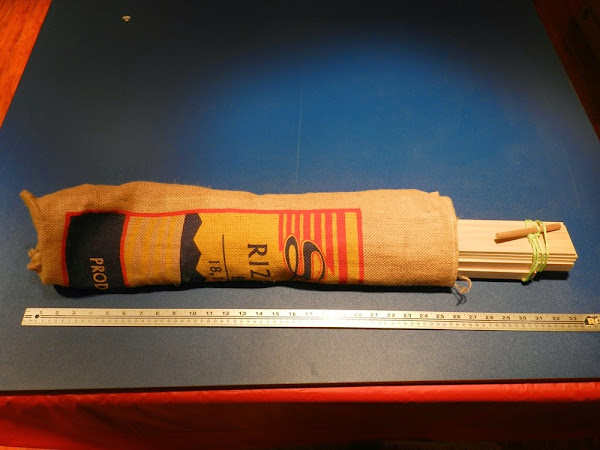

The take down process is quite fast and with the components stacked neatly and secured with the cordage it forms a nice bundle.

Here it is wrapped in the burlap sack. At 32" long, it just makes the cut for fitting in my Woods canvas pack. I also have an unused, narrow tent stuff sack that would be big enough to carry the whole thing and protect it from the elements if it needed to be lashed to the exterior. Final weight is 4.8lbs. Like I mentioned before, it'll never be as compact and lightweight as the Helinox chair, but I can live with weight difference.

Of course this is still in the raw stage. The wood hasn't been treated and I could tweak it a bit more but for now it is a functional chair. During one of our more balmy (-1C), depressing snowless January days here in Toronto, I took it out to the backyard for a little test. Here is the backyard campsite complete with a Mike McCrea inspired Fire in a Can.

Apparently it was designed by Dutch engineer Ole Gierløv Knudsen in 1962. The chair and an accompanying cot were created for a camping trip with his son. The original chairs from the 60s are apparently expensive collector's items today. You can see that the chair is held together by the tension of the windlass cord like a bucksaw. The whole thing collapses into a narrow stuff sac.

Certainly will never be as compact or lightweight as the modern Helinox Chairs that folks have been raving about, but I liked the concept. For a while I toyed with the idea of recreating the exact chair, using scrap canvas to sew the fabric and some hardwood for the frame components. But instead, I simplified the idea with whatever pre-fabricated scraps I had at home. All of the wood components were originally purchased (for other projects) at Home Depot, so they are pretty accessible. Here is what I came up with...

Little different that the original inspiration in that there are two windlass cords for the front and rear legs with a burlap sack for the backrest and wooden slats for a seat. But the concept of using tension similar to a bucksaw is the same.

Here are the components laid out from top to bottom

• the backrest fabric is a 17" w x 26" l burlap rice sack. I suppose an old pillow case or large nylon stuff sack could work too.

• seat slats are 3 loose pieces of 1/4" x 2.5" w x 24" l poplar panels

• 2 seat legs made from a remnant of dressed 1x2x8 of maple (actual dimensions are 3/4" x 1.5"w x 22" l)

• 2 backrest legs made from the same maple stock ( 3/4" x 1.5"w x 30" l)

• 2 3/4" poplar dowels for the cross braces (long one = 13.5"; short one is 11-7/8ths")

• some cordage and 1/4 dowel sticks

Unlike the original Bucksaw chair which has the seat legs nestled into a carved space on the exterior of the backrest frame, I ended simply attaching 2 cut block of maple onto each long using some glue and screws. Took some trial and error, but eventually settled on on placing these blocks so that the space created between would be 7" from the leg bottom. Also, I ended deviating from the Knudsen's design by purposely flipping the legs so that these notches facing inward rather than outward. The following sequence of pics might explain this better.

Here is the 1st step. Stick the long legs into the burlap sack with the "blocks" facing inward and tension with the cross piece and cord.

Then I place the other short legs into the support blocks and tension with the second dowel and cord. The tension created by the inner structure has a sort of friction lock at this stage. This is the view of the back of the chair...

Flip up and adjust how far back you want the chair to lean. This is accomplished by slightly squeezing the shorter seat legs towards each other near the block supports. The legs can then slide through the blocks and when you let go, they snap outwards again for an instant friction lock.

I had originally thought of using fabric for the seat again, but found that because of the width of the burlap back rest, something would need to be customized. I later got the inspiration from my 6 year old son who was playing with the 1/4" poplar boards building a sort of racetrack. I snagged 3 of his boards and found that they could easily rest, edge on edge on the projecting maple supports. Works well enought as a comfortable seat.

The take down process is quite fast and with the components stacked neatly and secured with the cordage it forms a nice bundle.

Here it is wrapped in the burlap sack. At 32" long, it just makes the cut for fitting in my Woods canvas pack. I also have an unused, narrow tent stuff sack that would be big enough to carry the whole thing and protect it from the elements if it needed to be lashed to the exterior. Final weight is 4.8lbs. Like I mentioned before, it'll never be as compact and lightweight as the Helinox chair, but I can live with weight difference.

Of course this is still in the raw stage. The wood hasn't been treated and I could tweak it a bit more but for now it is a functional chair. During one of our more balmy (-1C), depressing snowless January days here in Toronto, I took it out to the backyard for a little test. Here is the backyard campsite complete with a Mike McCrea inspired Fire in a Can.