- Joined

- Jul 6, 2021

- Messages

- 643

- Reaction score

- 1,180

I’ve been pondering Johnny 5’s Y webbing strap tower concept, and am intrigued with the idea of an easily attachable thwart tower.

https://www.canoetripping.net/threa...-own-removable-yoke.127250/page-2#post-132620

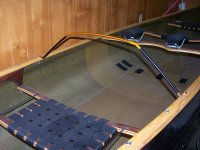

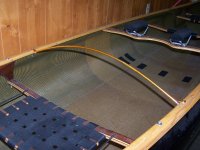

Not for a multi-point strap yoke, but for DIY spray cover reasons. The first two spray covers I made both had a (crude) raised “cowling” on the front cover. Crude as in section of old hula hoop in a sleeve, or Velcro attached.

When our OT Pack became a dedicated duck hunting marsh canoe it got attachable brush/pin oak holders, a gun rest, and waxed canvas camouflage covers; flat-ish in the stern, but hoop-raised in the bow for easier access to gear and decoys, better drainage from paddle drips or rain, and a bit more “hide” when sneakboating downriver.

That worked so well that one son’s first solo canoe, a 10’ OT Rushton, got the same raised bow cowling design, in lighter-weight coated nylon materials.

It worked, but the hula hoops, attached through PVC pipe clips on the inwales, were ugly and overly flexible.

A clamp-on center thwart tower has skirt raiser potential. I’m thinking a vertical tower, maybe 5” tall, with a rigid curved cowling piece at the top. That curved piece wouldn’t need to span gunwale to gunwale and be anchored though pipe clips to form the shape, it could just have 10 or 12 inches of curved arch sticking up, to form the top shape drape down to snaps.

Hard to draw on a keyboard, think this, (-- , stood upright.

I want to try an attachable thwart tower for a bow cowling arch the next time I DIY partial spray decks. Hey, maybe something with attachments I can festoon with my Go-Pro, GPS, cell phone and I-Pod ;-)

I have a variety of old, unused clamps, and have some long-unused pieces of steam bent wood to use for the top arch in lieu of colorful plastic hula hoops.

P1030014 by Mike McCrea, on Flickr

P1030014 by Mike McCrea, on Flickr

Those hula hooped cowlings were made 30 years ago. Who would have thought that I’d still have pieces of hula hoop in “shop stock”? I never doubted it, and there they are.

I have a feeling I’ll be reinventing the wheel; there must be designs for DIY clamp on thwart “towers”, or even some manufactured versions from which to copy.

Eh, on further thought, along my don’t like stuff above the sheerline, I’d want something that wouldn’t rip out the thwart in a capsize, or get stuck in a strainer mid rope retrieval. Anything sticking up above sheerline becomes potentially problematic in pinned rope drags.

Or even in boat-over-boat rescues; I was totally stymied by a bleach bottle bailer, thwart tied to dumped Magic; dangling attached on a short cord it prevented repeated effort at bow-over rescue, and was finally, laboriously, WTF I give up, bullnose plowed to shore inverted.

Maybe the flexible/sacrificial hula hoops weren’t such a bad idea. I still want to try again.

https://www.canoetripping.net/threa...-own-removable-yoke.127250/page-2#post-132620

Not for a multi-point strap yoke, but for DIY spray cover reasons. The first two spray covers I made both had a (crude) raised “cowling” on the front cover. Crude as in section of old hula hoop in a sleeve, or Velcro attached.

When our OT Pack became a dedicated duck hunting marsh canoe it got attachable brush/pin oak holders, a gun rest, and waxed canvas camouflage covers; flat-ish in the stern, but hoop-raised in the bow for easier access to gear and decoys, better drainage from paddle drips or rain, and a bit more “hide” when sneakboating downriver.

That worked so well that one son’s first solo canoe, a 10’ OT Rushton, got the same raised bow cowling design, in lighter-weight coated nylon materials.

It worked, but the hula hoops, attached through PVC pipe clips on the inwales, were ugly and overly flexible.

A clamp-on center thwart tower has skirt raiser potential. I’m thinking a vertical tower, maybe 5” tall, with a rigid curved cowling piece at the top. That curved piece wouldn’t need to span gunwale to gunwale and be anchored though pipe clips to form the shape, it could just have 10 or 12 inches of curved arch sticking up, to form the top shape drape down to snaps.

Hard to draw on a keyboard, think this, (-- , stood upright.

I want to try an attachable thwart tower for a bow cowling arch the next time I DIY partial spray decks. Hey, maybe something with attachments I can festoon with my Go-Pro, GPS, cell phone and I-Pod ;-)

I have a variety of old, unused clamps, and have some long-unused pieces of steam bent wood to use for the top arch in lieu of colorful plastic hula hoops.

P1030014 by Mike McCrea, on Flickr

P1030014 by Mike McCrea, on FlickrThose hula hooped cowlings were made 30 years ago. Who would have thought that I’d still have pieces of hula hoop in “shop stock”? I never doubted it, and there they are.

I have a feeling I’ll be reinventing the wheel; there must be designs for DIY clamp on thwart “towers”, or even some manufactured versions from which to copy.

Eh, on further thought, along my don’t like stuff above the sheerline, I’d want something that wouldn’t rip out the thwart in a capsize, or get stuck in a strainer mid rope retrieval. Anything sticking up above sheerline becomes potentially problematic in pinned rope drags.

Or even in boat-over-boat rescues; I was totally stymied by a bleach bottle bailer, thwart tied to dumped Magic; dangling attached on a short cord it prevented repeated effort at bow-over rescue, and was finally, laboriously, WTF I give up, bullnose plowed to shore inverted.

Maybe the flexible/sacrificial hula hoops weren’t such a bad idea. I still want to try again.