-

Happy National Bacon Day! 🐖🔪🔥🥓

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thoughts on a Bell Merlin ii (not that I'm looking for another canoe...)

- Thread starter FartherWest

- Start date

Regarding the aluminum gunwales, it was stored resting in metal racks that had rusted and weren't all that smooth. There are significant scratches and discoloration all around. The scratches go to the metal in several places as well.

I haven't had the chance to try cleaning this off yet, but any ideas on way to clean it would be greatly appreciated.

I haven't had the chance to try cleaning this off yet, but any ideas on way to clean it would be greatly appreciated.

G

Guest

Guest

Regarding the aluminum gunwales, it was stored resting in metal racks that had rusted and weren't all that smooth. There are significant scratches and discoloration all around. The scratches go to the metal in several places as well.

I haven't had the chance to try cleaning this off yet, but any ideas on way to clean it would be greatly appreciated.

Aluminum cleaner and brightener. Post 6 in this thread.

http://www.canoetripping.net/forums...-lots-of-questions-and-hopfully-a-few-answers

If that is an example of the worst of the scratches I would just clean the aluminum first, before trying any sanding or ect.

I think you’ll find rot or decay on the ends of at least the carry handles, probably enough that new ones are in order. Those Bell carry handles and thwarts are so distinctive it would be nice to use the same shape.

WRT to brightening up aluminum to make it shiny again... I've had good results with a wire wheel brush after filing and shaping old corroded aluminum... eg.

You might want to try on a piece of scrap aluminum before committing to the gunnels. Anyway, a nice pebbly, shiny surface is produced by the harder steel wire bristles.

You might want to try on a piece of scrap aluminum before committing to the gunnels. Anyway, a nice pebbly, shiny surface is produced by the harder steel wire bristles.

Congrats on your decisive new purchase and, with five total hulls, your sacred ascent into boatsluttery.

White gel coat is the best color to hide oxidation since the oxidation is also white. I'd wash the outside with a good scrub brush. If there is oxidation you could try polishing compounds, but I've never found them to be worth the time and hard manual effort. Just apply, and after five minutes wipe off, a coat of Penetrol, which takes about 10 minutes total for an entire canoe hull. That will make the oxidation optically, though not physically, disappear. (Oxidation causes micropits in the gel coat, and the pits cause incident light to scatter, giving a whitish appearance. Penetrol fills in the pits and stops the light scattering.) One application of Penetrol will last almost an entire season.

The inside of the Bell canoe is woven Kevlar, which indeed scuffs and even fuzzes with normal use. Or it might also be some whitish blushing of the peculiar resin, due to a reaction with moisture, that Bell used during certain years, as is true on my black-gold Wildfire. After washing, I clean the entire interior with acetone, which eliminates the resin blush, and then apply Penetrol, which shines it up.

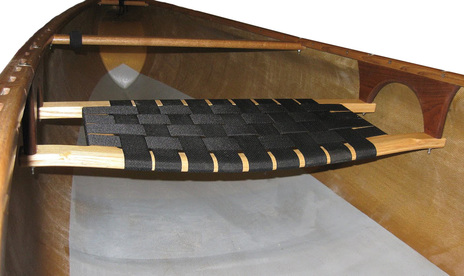

While Ed's is a long time standard for canoe parts, I would highly recommend the Conk contour seat made by Paul Conklin, a member of this forum. It's the most comfortable kneeling seat I've ever used in my 60+ years of canoeing. The front edge is not only curved downward but has a large radiused edge, so it doesn't cut into the back of your thigh. The back rail is straight, which supplies good support for seated paddling. It's laminated of two woods, so is both stronger and lighter than a solid ash or cherry seat. I installed one in my Bell Wildfire and it fit perfectly on the Bell drops. I also installed one on my SRT. I'm not sure whether Conk still sells them only through Hemlock Canoe, as they are now being used as standards by Colden Canoe and Savage River, but you can definitely buy the seats from Hemlock. HERE is the product page from Hemlock and here is a Hemlock photo:

Here is my 15 year old Bell Wildfire with Conk seat installed and after being cleaned with acetone and Penetrol. It was in cruddy shape before the cleaning.

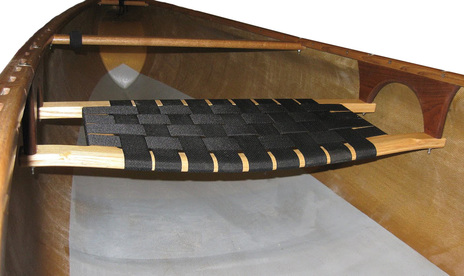

Here is a closeup of the interior (intended actually to show a gunwale repair):

White gel coat is the best color to hide oxidation since the oxidation is also white. I'd wash the outside with a good scrub brush. If there is oxidation you could try polishing compounds, but I've never found them to be worth the time and hard manual effort. Just apply, and after five minutes wipe off, a coat of Penetrol, which takes about 10 minutes total for an entire canoe hull. That will make the oxidation optically, though not physically, disappear. (Oxidation causes micropits in the gel coat, and the pits cause incident light to scatter, giving a whitish appearance. Penetrol fills in the pits and stops the light scattering.) One application of Penetrol will last almost an entire season.

The inside of the Bell canoe is woven Kevlar, which indeed scuffs and even fuzzes with normal use. Or it might also be some whitish blushing of the peculiar resin, due to a reaction with moisture, that Bell used during certain years, as is true on my black-gold Wildfire. After washing, I clean the entire interior with acetone, which eliminates the resin blush, and then apply Penetrol, which shines it up.

While Ed's is a long time standard for canoe parts, I would highly recommend the Conk contour seat made by Paul Conklin, a member of this forum. It's the most comfortable kneeling seat I've ever used in my 60+ years of canoeing. The front edge is not only curved downward but has a large radiused edge, so it doesn't cut into the back of your thigh. The back rail is straight, which supplies good support for seated paddling. It's laminated of two woods, so is both stronger and lighter than a solid ash or cherry seat. I installed one in my Bell Wildfire and it fit perfectly on the Bell drops. I also installed one on my SRT. I'm not sure whether Conk still sells them only through Hemlock Canoe, as they are now being used as standards by Colden Canoe and Savage River, but you can definitely buy the seats from Hemlock. HERE is the product page from Hemlock and here is a Hemlock photo:

Here is my 15 year old Bell Wildfire with Conk seat installed and after being cleaned with acetone and Penetrol. It was in cruddy shape before the cleaning.

Here is a closeup of the interior (intended actually to show a gunwale repair):

G

Guest

Guest

A noted canoe builder paints the interiors with porch and deck paint. I have used this to remove the Kevlar roughness from underneath the seat which abrades my bare feet. On my latest boat I used rustolem marine paint for this.

Turtle

Turtle

My MerlinII had the amine blush and also wore the finish off part of the floor.

A light coat of marine varnish did the trick. I haven't used Penetrol except on T111 house siding and do t know if it provides a barrier to further fuzzing of Kevlar. You don't want Kevlar unprotected

Varnish does protect

A light coat of marine varnish did the trick. I haven't used Penetrol except on T111 house siding and do t know if it provides a barrier to further fuzzing of Kevlar. You don't want Kevlar unprotected

Varnish does protect

G

Guest

Guest

Congrats on your decisive new purchase and, with five total hulls, your sacred ascent into boatsluttery.

I think the least we can do is help Kathy pick out the next niche boat in her fleet. Let’s see, so far on the racks:

Tiderace Xcite

Tiderace Xplore-M

Jackson Fun Runner

15 foot Prospector (which make/model?)

Bell Merlin II

Dang, what’s left? A folder or inflatable to fly with?

There must be some good open water and wind near Portland, maybe a sailing canoe (or kayak)? Or a 12 lb pack canoe for small hike-in lake in the Cacades?

No boatsluttery finger pointing from me. We have 16 boats right now, down from a high of 24-25. Everyone in the family has a favorite flat water canoe, a moving water canoe, a tripping canoe and a decked tripping sailer.

While Ed's is a long time standard for canoe parts, I would highly recommend the Conk contour seat made by Paul Conklin, a member of this forum. It's the most comfortable kneeling seat I've ever used in my 60+ years of canoeing. The front edge is not only curved downward but has a large radiused edge, so it doesn't cut into the back of your thigh. The back rail is straight, which supplies good support for seated paddling. It's laminated of two woods, so is both stronger and lighter than a solid ash or cherry seat.

Yup, next solo seat I install will be a Conk.

A noted canoe builder paints the interiors with porch and deck paint. I have used this to remove the Kevlar roughness from underneath the seat which abrades my bare feet.

I am leery of deck paint on a canoe, except in small, high scuff areas. That stuff is thick and heavy, and is a favorite of semi-scammy folks trying to cover gel coat spider cracks on a used composite canoe.

I’d rather roll and tip out a coat or two of epoxy resin on wear areas, wet sand that and then top coat with clear varnish or urethane. I expect that if a noted builder uses it it’s OK in small areas, but deck paint on a canoe makes me suspect.

- Joined

- Jun 22, 2017

- Messages

- 1,243

- Reaction score

- 3,096

The conk seat looks like another nice option and in Glenn's picture you can also see the painted bottom used by Hemlock Canoe. I have no experience with Penetrol...I'd lean towards paint or varnish on the inside to make sure it gets well sealed.

Your gunnels are fine and there is no need to sand them. I think a steel wool pad or SOS pad will clean them right up if you have one on hand...although the other ideas seem great too (aluminum cleaner or wire wheel).

Your carrying handles and thwarts do show some sign of water rot on the ends. It's easy to take them off and sand them down and then you can decide if you want to reuse them or if the rot is bad enough to warrant replacing them. For sure it is a good idea to give the ends a good soaking in whatever oil you use (like overnight) before reinstalling. I used Watco on a Swift Shearwater I bought used that had spent a lot of time outside where the ends of the wood had started to deteriorate like yours since it seems like it has a harder finish versus oil but that may be my imagination.

When I clean up an extra dirty boat that has not been cleaned for a very long time I just use Bon Ami since it's non-abrasive. Then my boats just get a bubble bath using dish soap a couple times a year, plus 303 once in a while on the hull and a little gunnel lotion on the wood occasionally.

Mike - fair point around the machine screws. I may not have an entrapment risk with my petite size 11s but for sure there is a puncture wound risk. My entrapment memory is when the accelerator on my 86 Mustang GT would get trapped by the floormat but only when you pushed the accelerator all the way down. Quite thrilling...

Your gunnels are fine and there is no need to sand them. I think a steel wool pad or SOS pad will clean them right up if you have one on hand...although the other ideas seem great too (aluminum cleaner or wire wheel).

Your carrying handles and thwarts do show some sign of water rot on the ends. It's easy to take them off and sand them down and then you can decide if you want to reuse them or if the rot is bad enough to warrant replacing them. For sure it is a good idea to give the ends a good soaking in whatever oil you use (like overnight) before reinstalling. I used Watco on a Swift Shearwater I bought used that had spent a lot of time outside where the ends of the wood had started to deteriorate like yours since it seems like it has a harder finish versus oil but that may be my imagination.

When I clean up an extra dirty boat that has not been cleaned for a very long time I just use Bon Ami since it's non-abrasive. Then my boats just get a bubble bath using dish soap a couple times a year, plus 303 once in a while on the hull and a little gunnel lotion on the wood occasionally.

Mike - fair point around the machine screws. I may not have an entrapment risk with my petite size 11s but for sure there is a puncture wound risk. My entrapment memory is when the accelerator on my 86 Mustang GT would get trapped by the floormat but only when you pushed the accelerator all the way down. Quite thrilling...

A noted canoe builder paints the interiors with porch and deck paint. I have used this to remove the Kevlar roughness from underneath the seat which abrades my bare feet. On my latest boat I used rustolem marine paint for this.

Turtle

Some boat builders provide oval scuff patches. Mike Galt made them out of gel coat, but Dave Curtis says that that is very hard to do with the excellent aesthetic results that Galt was able to achieve. The scuff patches used to be made of some sort of "paint" material that is now illegal for some real or fancied environmental reason. I think that's why deck paint is now being used instead.

I can't imagine that Penetrol could physically repair frayed or debrided Kevlar, although it may make it look better. That would require some sort of actual physical barrier such as urethane or paint. But that barrier will eventually wear away and look ugly.This is my SRT with a 14 year old painted scuff patch:

I use large kneeling pads in front of the seat, although not necessarily as large as the pad shown in my Wildfire a couple posts up, which has an extra large pad for repositioning during Freestyle play.

G

Guest

Guest

I came across the seldom used wire wheel in the shop, thought about its use and complications on aluminum gunwales and got the willies. I would not use a wire wheel on your aluminum gunwales unless everything else has been tried and failed. And probably not then.

Kinda like using solvents, it is often best to start with the least aggressive treatment and progress to harsher solutions only if needed.

I’d recommend starting with an aluminum cleaner/brightner product and a ScotchBrite pad, or even just soapy water and a ScotchBrite pad. Maybe some marine wax after they are clean to help fill and hide any existing scratches.

The ScotchBrite pad with aluminum cleaner dulled the aluminum to a near matt finish when I used it in that fashion (the cleaner instructions say simply wipe on and rinse off).

Something high speed whirling like a wire wheel might quickly do more harm than good, and I’d be dang leery about getting it too close to the hull material near the undersides of the gunwales.

Kinda like using solvents, it is often best to start with the least aggressive treatment and progress to harsher solutions only if needed.

I’d recommend starting with an aluminum cleaner/brightner product and a ScotchBrite pad, or even just soapy water and a ScotchBrite pad. Maybe some marine wax after they are clean to help fill and hide any existing scratches.

The ScotchBrite pad with aluminum cleaner dulled the aluminum to a near matt finish when I used it in that fashion (the cleaner instructions say simply wipe on and rinse off).

Something high speed whirling like a wire wheel might quickly do more harm than good, and I’d be dang leery about getting it too close to the hull material near the undersides of the gunwales.

Congrats on your decisive new purchase and, with five total hulls, your sacred ascent into boatsluttery.

ROFLMAO

- SUP's - I'm to lazy to use those. If I want to SUP, I take my canoe and stand up and paddle it around. I've done it a few times and enjoyed the experience. I need to learn to pole and balance is part of that.

- Sailing canoe - I am strongly considering doing that to the Prospector (Wenonah, 15 ft, tuff weave) Switch out one of the seats and order the parts from the UK. I have a list but keep spending $$ on other things...

- Fold-ups/ inflatables... see earlier comments about being lazy. And while I might be full of hot air from time to time... I'm not sure I'm that bad.

With respect to the gunwales - the idea of a wire wheel made me cringe too. I can see the use if the damage is extensive, but as a few of you have noted, I'll start with the least abrasive option first. My biggest concern with any option is removing the gold anodized finish from the gunwales. It is a very nice look and if it comes off.. that would be unfortunate. Especially if painting them isn't really feasible/advisable, that leaves me with few options (replace with aluminum or wood gunwales down the road). But first steps fist, see how it looks cleaned up.

Thanks for the tip on Bon Ami, I'll pick that up with some fine grade steel wool and we'll see what happens.

Floor condition - I would like to use something that seals the floor and the fibers from absorbing water, I realize how important that is. Glenn: The process you outlined, and that a few others mentioned, is what I had in mind to get a solid barrier in place. Can you be more specific as far as the products you would suggest? (epoxy resin on wear areas, wet sand that and then top coat with clear varnish or urethane)

Thwarts/handles - The harder the finish the better so I might end up ordering the Watco (also found it on Ed's). I'd also like to reuse the original pieces if at all possible to keep the integrity of the canoe (ie: shape of the woodwork, etc). If I cant, then I'll try to keep the shapes as close to the original as possible.

Glenn - If I could get this little lady to look 1/2 as good as your Wildfire that would be awesome!

Thank you all for the feedback and ideas - I so appreciate it!

Kathy

You did good Kathy, I just saw a Merlin II being offered for $ 2200.00.

G

Guest

Guest

ROFLMAOWhy do I get the feeling around here, that might actually be a compliment?

We are all boat sluts here. Welcome to the club.

SUP's - I'm to lazy to use those. If I want to SUP, I take my canoe and stand up and paddle it around. I've done it a few times and enjoyed the experience. I need to learn to pole and balance is part of that.

Me too. My wife enjoys SUPing, and has taken classes up to advanced. I asked if she was interested in buying a SUP and she was “Meh.. . . . .”

Sailing canoe - I am strongly considering doing that to the Prospector (Wenonah, 15 ft, tuff weave) Switch out one of the seats and order the parts from the UK. I have a list but keep spending $$ on other things...

I had wondered what make/model your Prospector was. Nice boat. If you get it out tandem in the open water breeze try handing your bowman a golf umbrella. That’s all it took to sell me on the joys of downwind sailing. Do remember that you have to get back to the launch somehow.

Fold-ups/ inflatables... see earlier comments about being lazy. And while I might be full of hot air from time to time... I'm not sure I'm that bad.

I know a few folks who air travel extensively with folders, and they are well practiced at putting the dang things together. I’d still prefer a boat I can untie from the roof racks and be gone. And the last time I flew to Norway or Greenland with a boat was, uh, never.

I'll start with the least abrasive option first. My biggest concern with any option is removing the gold anodized finish from the gunwales. It is a very nice look and if it comes off.. that would be unfortunate. Especially if painting them isn't really feasible/advisable, that leaves me with few options (replace with aluminum or wood gunwales down the road). But first steps fist, see how it looks cleaned up.

I did not realize the gunwales were anodized gold. I’d start with soap and water and a plastic backed scrubbie, and if that proves unsatisfactory try aluminum cleaner, sans the Scotchbrite pad at least at first.

Floor condition - I would like to use something that seals the floor and the fibers from absorbing water, I realize how important that is. Glenn: The process you outlined, and that a few others mentioned, is what I had in mind to get a solid barrier in place. Can you be more specific as far as the products you would suggest? (epoxy resin on wear areas, wet sand that and then top coat with clear varnish or urethane)

I have a distaste for deck paint on canoes. Admittedly that is based largely on used canoe sellers hiding gel coat cracks while adding 10 lbs to the weight of a hull. For a small interior scuff patch it is probably OK.

My deck paint avoidance is enough that I would roll out a coat of epoxy resin, lay release treated peel ply over that to compress any kevlar fuzz and then wet sand the resultant faint weave from the peel ply and top coat with spar urethane. That is a lot more product and work steps than taping out a diamond box and laying down some deck paint, but I have time and all of the needed materials.

Thwarts/handles - The harder the finish the better so I might end up ordering the Watco (also found it on Ed's). I'd also like to reuse the original pieces if at all possible to keep the integrity of the canoe (ie: shape of the woodwork, etc). If I cant, then I'll try to keep the shapes as close to the original as possible.

I do like oil on wood gunwales for the easy of re-treatment, but I am not a big fan of oil finishes on brightwork cross members. I’d rather use good UV protective spar varnish or spar urethane and not have to mess with those pieces for 10 years. See this test (photos are probably gone, descriptive text remains):

http://www.myccr.com/phpbbforum/viewtopic.php?f=49&t=40923

If your Bell distinctive carry handles and thwart are not too far gone at the blackened butt ends I’d try sanding them clean and recoating with Helmsman Spar Urethane, paying special attention to getting 3+ coats on the butt ends.

Mike...

The way I thought it could be done would be to mask off the hull with a clamped piece of sheet metal held in place at the edge of the aluminum and that would protect the hull material from the wire wheel. Or to remove the gunwale if possible (unless rivets need to be removed). Only one option, and I'd probably go with something safer myself. Still, gives a very nice finish.

I came across the seldom used wire wheel in the shop, thought about its use and complications on aluminum gunwales and got the willies. I would not use a wire wheel on your aluminum gunwales unless everything else has been tried and failed. And probably not then.

The way I thought it could be done would be to mask off the hull with a clamped piece of sheet metal held in place at the edge of the aluminum and that would protect the hull material from the wire wheel. Or to remove the gunwale if possible (unless rivets need to be removed). Only one option, and I'd probably go with something safer myself. Still, gives a very nice finish.

G

Guest

Guest

The way I thought it could be done would be to mask off the hull with a clamped piece of sheet metal held in place at the edge of the aluminum and that would protect the hull material from the wire wheel. Or to remove the gunwale if possible (unless rivets need to be removed). Only one option, and I'd probably go with something safer myself. Still, gives a very nice finish.

I don’t do a lot of metal work (see barefoot babes in the shop), and would worry about my unpracticed “touch” with a wire wheel.

I use little 1 inch belt sanders almost every day for custom fitment work and have absolutely developed a “touch” with those tools. I may be approaching the requisite 10,000 hours of practice to master that task, and have a lot of confidence in my ability to incrementally power sand down just the right amount.

With a wire wheel, not so much. Not being a metalworking guy I didn’t think about clamping sheet metal hull protection under the wales. Not that I happen to have long lengths of sheet metal around to clamp in place.

I hate taking otherwise sound gunwales off to just to work on them. My ability to reinstall gunwales so they precisely hit the existing holes, as initially drilled, and not elongated re-drilled through the sheerline, is close to nil. Or at best a product of 20 hours of frustrated dammit malpractice.

I still don’t see how people do that. I just off-set new through gunwale holes, and sometimes run a strip of E-glass tape and epoxy along the sheerline to fill the old holes. A 16 foot canoe = 30+ screws or pop rivets through the sheerline on the OEM set of gunwales. 60 holes total

If the hull had been regunwaled before think 120 holes. Too Swiss-cheesy along the sheerline for me with adding a length of glass tape.

I say leave those (gold anodized) gunwales be; just gently clean them up and maybe wax them.

Regarding the aluminum gunwales, it was stored resting in metal racks that had rusted and weren't all that smooth. There are significant scratches and discoloration all around. The scratches go to the metal in several places as well.

I haven't had the chance to try cleaning this off yet, but any ideas on way to clean it would be greatly appreciated.

The clean aluminum gunnels of my new ultralight canoe spent quite a trips on the bare, black metal rack of friends vehicle. Left ugly black marks in several locations.

I cleaned it up by usin 220 grit sandpaper on a random orbital sander, and feathered in the edges with 0000 steel wool. Came out fine.

- Joined

- Jun 22, 2017

- Messages

- 1,243

- Reaction score

- 3,096

The plot thickens...

I think you may have actually gotten a black/gold lay-up with a colored (instead of clear) gel coat which was available as an option. The interior sure does look like a black/gold boat. I can't tell if your boat has a foam core or if we just see triangular patches of Kevlar...can you tell? Black/gold Merlin II's did not have a foam core.; I just double checked mine. White/gold had a foam core (I think). It's not a lightweight Kevlar boat (lucky for you) and I thought the white/gold boats lacked the black part of the checkerboard pattern that you can see in your boat's interior.

Plus your thwarts DO appear to be black walnut and I believe that was only on black/gold boats. Your carrying handles are ash and that was same on all 3 Bell lay-ups. Your thwarts look SO dry, so at the risk of being hit by lighting I'm going to suggest that you put a little olive oil on them immediately until you get whatever else you want to treat them with. If you don't oil them soon I will mail you a small container of gunnel lotion.

I think you could now get $1400 from Steve in Idaho. And you can tell your husband that your boat is an investment that has already appreciated by 50 percent.

Unfortunately, with just one lake-biased solo and one highly rockered versatile tandem, I also have to downgrade your status to Emerging Canoe Enthusiast.

I think you may have actually gotten a black/gold lay-up with a colored (instead of clear) gel coat which was available as an option. The interior sure does look like a black/gold boat. I can't tell if your boat has a foam core or if we just see triangular patches of Kevlar...can you tell? Black/gold Merlin II's did not have a foam core.; I just double checked mine. White/gold had a foam core (I think). It's not a lightweight Kevlar boat (lucky for you) and I thought the white/gold boats lacked the black part of the checkerboard pattern that you can see in your boat's interior.

Plus your thwarts DO appear to be black walnut and I believe that was only on black/gold boats. Your carrying handles are ash and that was same on all 3 Bell lay-ups. Your thwarts look SO dry, so at the risk of being hit by lighting I'm going to suggest that you put a little olive oil on them immediately until you get whatever else you want to treat them with. If you don't oil them soon I will mail you a small container of gunnel lotion.

I think you could now get $1400 from Steve in Idaho. And you can tell your husband that your boat is an investment that has already appreciated by 50 percent.

Unfortunately, with just one lake-biased solo and one highly rockered versatile tandem, I also have to downgrade your status to Emerging Canoe Enthusiast.

It's easy enough to determine whether it's white or black gold: weigh it. A black-gold with aluminum gunwales should be in the mid 30's; the white-gold, about ten pounds heavier.

For a more technical description of Bell's lamination schedules, HERE are Charlie Wilson's notes from 1994 when he was a principal at Bell. Some excerpts:

"White / Gold had an e glass outer blanket under a gel coated exterior, an arimide bottom with a core mat center, an arimide blanket, an arimide diamond and another arimide inner blanket that, after the mid 90's was 25% black Kevlar 29 and 75% Kevlar 49, the Bell "tweed".

"Both Fiberlar and White/Gold hulls had a cor-mat bottom cookie, which stiffens the bottom but resists deformation when thwart length is fiddled. Core mat cores always seemed to flatten the boats a little compared to Black/Gold, all fabric, construction.

"Aluminum rails tend to hog the boat as they are not pre-shaped and the lightweight laminate drops it's stems a little from the straightening effect of the rails along the sheerline.

"Black/Gold started with clear gel, which could be special ordered opaque and is now often skin coated. The lamination starts with a carbon blanket, carbon bottom and center diamond, all black, then a tweed blanket, a tweed bottom and diamond and another tweed inner blanket. Newer black/gold hulls may have foam cores."

So, both white and black gold laminates had Kevlar "tweed" inner blankets. The Bell tweed is all Kevlar, colored yellow and black on the warp and woof, not a bi-weave of Kevlar and carbon such as Hemlock uses. The white-golds have a coremat patch (or "cookie") on the bottom whereas the black-golds initially were all Kevlar and carbon, except for some foam core bottoms on some later canoe models, primarily tandems and the Magic.

For a more technical description of Bell's lamination schedules, HERE are Charlie Wilson's notes from 1994 when he was a principal at Bell. Some excerpts:

"White / Gold had an e glass outer blanket under a gel coated exterior, an arimide bottom with a core mat center, an arimide blanket, an arimide diamond and another arimide inner blanket that, after the mid 90's was 25% black Kevlar 29 and 75% Kevlar 49, the Bell "tweed".

"Both Fiberlar and White/Gold hulls had a cor-mat bottom cookie, which stiffens the bottom but resists deformation when thwart length is fiddled. Core mat cores always seemed to flatten the boats a little compared to Black/Gold, all fabric, construction.

"Aluminum rails tend to hog the boat as they are not pre-shaped and the lightweight laminate drops it's stems a little from the straightening effect of the rails along the sheerline.

"Black/Gold started with clear gel, which could be special ordered opaque and is now often skin coated. The lamination starts with a carbon blanket, carbon bottom and center diamond, all black, then a tweed blanket, a tweed bottom and diamond and another tweed inner blanket. Newer black/gold hulls may have foam cores."

So, both white and black gold laminates had Kevlar "tweed" inner blankets. The Bell tweed is all Kevlar, colored yellow and black on the warp and woof, not a bi-weave of Kevlar and carbon such as Hemlock uses. The white-golds have a coremat patch (or "cookie") on the bottom whereas the black-golds initially were all Kevlar and carbon, except for some foam core bottoms on some later canoe models, primarily tandems and the Magic.

Similar threads

- Replies

- 9

- Views

- 800

- Replies

- 13

- Views

- 393

- Replies

- 14

- Views

- 2K

- Replies

- 17

- Views

- 3K