G

Guest

Guest

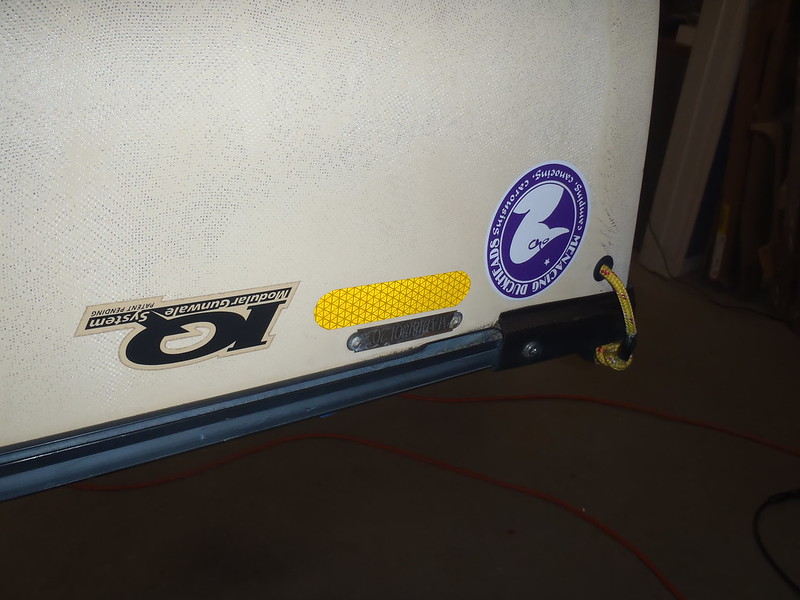

I have a white composite Malecite that is the worst dirt magnet of any boat I have encountered, and I have owned other white canoes.

It is not just the color, the white gel coat was so thinly applied that the underlying weave of the cloth faintly shows through the gel coat.

That canoe would pick up a scum line if I paddled it in a pool of Perrier. Worse, every bit of pollen, pollution and road trip grime embeds in the visible weave. I wash it after trips, but even with some elbow grease and soft bristle brushing it is impossible to get all of the embedded grime out of the weave. In that weave begrimed state the otherwise attractive Malecite is fugly.

The question is how to fill that weave after the next time I scrub it clean

I have washed and scrubbed the Malecite. Multiple times with different cleaning agents. The gel coat really is super thin; you can see the underlying weave pattern in the gel coat, and feel it with your fingers, especially now that the weave filling crud is gone.

On the other hand I have abused the hell out of that boat, even cracked (and repaired) the bottom on one memorable trip, and that super thin gel coat has yet to develop a single spider crack. There is something to be said for a thin gel coat layer. Just not this thin.

I had detail scrubbed the Malecite earlier this summer, and it was already beyond filthy again. Time for some serious elbow grease dirt, pollen and pollution removal. I washed it with a grime-removing car wash soap. Twice; the second time very little additional crud was coming out from the weave. It was less grimy, but still weave embedded dirt pimpled.

So I tried DougD’s homemade PowerShot mix, a straight 50/50 mix of Dawn and white vinegar, no water, and scrubbed it with a soft bristle brush. Twice, going back over any area I had missed. Better, but still a little dirt pimpled in some very weave exposed areas, especially at the stems. What the hell, I have the hose, bucket and brush out, I detail scrubbed it a final time with the car wash grime soap, to little additional rinse color in the bucket.

If you are counting I washed the canoe 5 times today. My elbow hurts and I have given up trying to get it any cleaner.

The entire hull is now a matt-finish dull and the exposed weave even more apparent to the eye, and touch, especially now that the voids are not filled with self-fairing crud.

It is ready for some topcoat to fill that dirt magnet weave, and I am stumped. I had thought that buffing on a couple coats of marine wax might do, but wax may not be sufficient to fill that exposed weave depth. And if I wax it and do not like the result it is back to 5-stage scrubbing to remove all of the wax before applying a top coat.

So I’m thinking - alcohol wipe it, tape off the gunwales and:

Paint the entire outside with spar urethane, which I have

Or with a hull-matching cream colored enamel paint, which I can easily get

Or use something like off-white Petit Easypoxy, which I have never used but could order.

I think I know which way I should go, but what says you?