So I bought plans for a J Winters Kite...it's a 15 ft solo, with a radically cut tumblehome and differential rocker, an improved Ospey (or so I'm told).

My current solo, a stripped DY Special, is a joy to behold and paddle...in most conditions. It is not well suited for big water with following winds (killer stern hook) and is built for going straight. Even though I managed to keep the weight at 31 lbs, I want something better suited for some of the waters that I prefer, not too distant ponds (less than 5 mile carry), beaver flows, smalls streams and class II rivers.

Specifically, I want a solo that's lighter in weight, more maneuverable, safer in big water, and can take a beating. Also, I like a variety of paddling positions, but NOT pack boat sit on the bottom style. I much prefer sit 'n switch and kneeling, always with a single bent shaft. Capacity is not an issue, I'm still a welterweight and my gear rarely weighs more than 30 lbs.

I'm hoping to keep the weight to 25 lbs, we'll see.

I'm trying out a few different build techniques this time around. Laminated stems, only because of the wide, blunt stem designs. Carbon/kevlar over foam for the gunnels (to reduce weight). Carbon/foam seat frames and thwarts, again for weight considerations. Plenty of Dynel at the stems, for abrasion resistance, still not a better material available. An opaque exterior finish, likely pigmented resin, partly to hide the Dynel, partly to hide the inevitable rock damage. Lastly, cove and bead strips, to keep the hull as fair as possible.

So, now that everyone knows my criteria and motivations, here are some photos.

Form layout, 3/4 ply leftover from a large shipping crate. My CJ5 with BST's in the background (Big Stupid Tires)

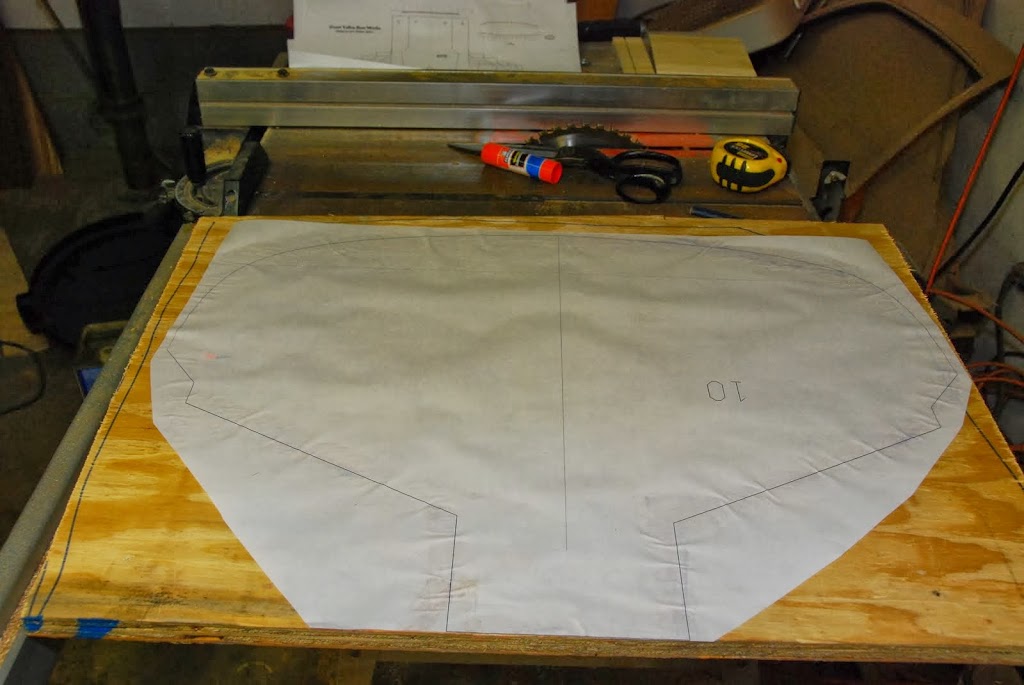

One of the forms, printed full size and glue sticked onto the plywood.

Yours truly, with my 25 year old Grizzly, still going strong

A very cluttered boat shop... a new fridge for one of the income properties, a Kawasaki that will be sold in the spring, a Triumph that need retitling, my SIL's compressor, and a pile of forms.

Not seen is half of an Opel GT (my son's residue), my compressor, spare Jeep parts.

A somewhat cleaner shop, with the forms stacked on a swiss cheesed strongback. Strongback has had a dozen or so different designs built on it, and double that in number of builds.

Aligned forms, with laminated but not trimmed stem pieces. Also, leftover strips from some previous builds and 3 new 1 x 6 cedar planks.

As of yesterday, I had all of the cedar cut into strips. I still need to plane the strips to all have a uniform thickness, then bead and cove them on the shaper. Also need to trim the stem piece shape and put some tape on the forms. The next few evenings will be pretty cold, and I can't fit the strips entirely within the boat shop. I would have to run the strips through the shaper and out into the unheated part of my garage...maybe I'll just wait a few days before planing and shaping.

Any questions??

My current solo, a stripped DY Special, is a joy to behold and paddle...in most conditions. It is not well suited for big water with following winds (killer stern hook) and is built for going straight. Even though I managed to keep the weight at 31 lbs, I want something better suited for some of the waters that I prefer, not too distant ponds (less than 5 mile carry), beaver flows, smalls streams and class II rivers.

Specifically, I want a solo that's lighter in weight, more maneuverable, safer in big water, and can take a beating. Also, I like a variety of paddling positions, but NOT pack boat sit on the bottom style. I much prefer sit 'n switch and kneeling, always with a single bent shaft. Capacity is not an issue, I'm still a welterweight and my gear rarely weighs more than 30 lbs.

I'm hoping to keep the weight to 25 lbs, we'll see.

I'm trying out a few different build techniques this time around. Laminated stems, only because of the wide, blunt stem designs. Carbon/kevlar over foam for the gunnels (to reduce weight). Carbon/foam seat frames and thwarts, again for weight considerations. Plenty of Dynel at the stems, for abrasion resistance, still not a better material available. An opaque exterior finish, likely pigmented resin, partly to hide the Dynel, partly to hide the inevitable rock damage. Lastly, cove and bead strips, to keep the hull as fair as possible.

So, now that everyone knows my criteria and motivations, here are some photos.

Form layout, 3/4 ply leftover from a large shipping crate. My CJ5 with BST's in the background (Big Stupid Tires)

One of the forms, printed full size and glue sticked onto the plywood.

Yours truly, with my 25 year old Grizzly, still going strong

A very cluttered boat shop... a new fridge for one of the income properties, a Kawasaki that will be sold in the spring, a Triumph that need retitling, my SIL's compressor, and a pile of forms.

Not seen is half of an Opel GT (my son's residue), my compressor, spare Jeep parts.

A somewhat cleaner shop, with the forms stacked on a swiss cheesed strongback. Strongback has had a dozen or so different designs built on it, and double that in number of builds.

Aligned forms, with laminated but not trimmed stem pieces. Also, leftover strips from some previous builds and 3 new 1 x 6 cedar planks.

As of yesterday, I had all of the cedar cut into strips. I still need to plane the strips to all have a uniform thickness, then bead and cove them on the shaper. Also need to trim the stem piece shape and put some tape on the forms. The next few evenings will be pretty cold, and I can't fit the strips entirely within the boat shop. I would have to run the strips through the shaper and out into the unheated part of my garage...maybe I'll just wait a few days before planing and shaping.

Any questions??