Hey all, those who have been following my experimental Strip build may have already seen some photos from my test paddle Monday. Overall, a good test. However.... One item did not work out as well as I had hoped.

My lovely, laminated seat frame did not survive the day.

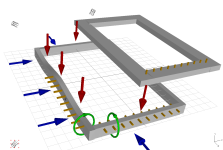

I'm a little nonplussed about this in two different ways. First, the original failure point is circled in red. I was seated with my weight forward, playing with the trim of the canoe. The slide block gave way at an epoxy joint, and the off-center load then twisted the seat frame.

The slide blocks are hard maple, assembled with thickened epoxy (SystemThree General Purpose + Cabosil) As you can see, in this case I actually had a glue joint failure, rather than the wood grain failure that I would have expected. I find this a bit disturbing, as this is the exact same glue that was used for some of my gunwale layup. The bond area was 3/4" X 1 1/2", under shear load, no peel.

Obviously, I can reinforce with pins, &tc, but I'm surprised that this happened in the first place. I can also flip the blocks upside-down, and set the seats above the slides. There is a steel bushing all the way through at the bolt locations, but this has the seats a bit higher than I planned. Do any of you see anything obvious, other than that Maple apparently does not absorb resin well?

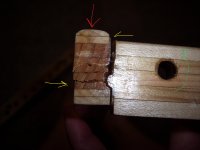

The other disappointment is that the seat frame failed that thoroughly. Take a look:

So, the cedar core cracked, which is not much of a surprise, but I'm also seeing in a couple of locations that the glue bond failed on both ends of the pins. I could just pass this off as the seat taking a load that it was not designed for, but I'm not that large, and I'd hoped for a little more resilience. I'm hesitant to trust the other frames at this point.

I really liked how these felt in hand, so I'm considering rebuilding in hardwood. I have plenty of Cherry and Walnut available, as well as more Maple, or we have Red Oak coming out our ears. (I Really don't want to do Oak for anything canoe related, though.) Even a full hardwood frame does not, though, fix the joint strength issues. Any insight would be welcome, though I'm afraid a replacement will end up heavier (These were about 2# including webbing)

My lovely, laminated seat frame did not survive the day.

I'm a little nonplussed about this in two different ways. First, the original failure point is circled in red. I was seated with my weight forward, playing with the trim of the canoe. The slide block gave way at an epoxy joint, and the off-center load then twisted the seat frame.

The slide blocks are hard maple, assembled with thickened epoxy (SystemThree General Purpose + Cabosil) As you can see, in this case I actually had a glue joint failure, rather than the wood grain failure that I would have expected. I find this a bit disturbing, as this is the exact same glue that was used for some of my gunwale layup. The bond area was 3/4" X 1 1/2", under shear load, no peel.

Obviously, I can reinforce with pins, &tc, but I'm surprised that this happened in the first place. I can also flip the blocks upside-down, and set the seats above the slides. There is a steel bushing all the way through at the bolt locations, but this has the seats a bit higher than I planned. Do any of you see anything obvious, other than that Maple apparently does not absorb resin well?

The other disappointment is that the seat frame failed that thoroughly. Take a look:

So, the cedar core cracked, which is not much of a surprise, but I'm also seeing in a couple of locations that the glue bond failed on both ends of the pins. I could just pass this off as the seat taking a load that it was not designed for, but I'm not that large, and I'd hoped for a little more resilience. I'm hesitant to trust the other frames at this point.

I really liked how these felt in hand, so I'm considering rebuilding in hardwood. I have plenty of Cherry and Walnut available, as well as more Maple, or we have Red Oak coming out our ears. (I Really don't want to do Oak for anything canoe related, though.) Even a full hardwood frame does not, though, fix the joint strength issues. Any insight would be welcome, though I'm afraid a replacement will end up heavier (These were about 2# including webbing)