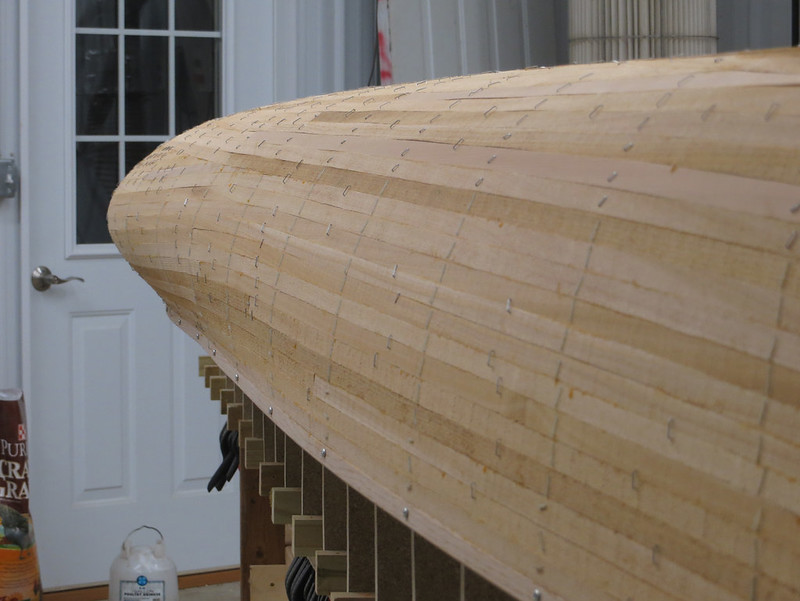

I don't know what to call it yet. I might call it a POS once it hits the water. Trying my hand at designing my own canoe. It's meant to be a workout/racing boat and not much else but more user friendly than something like C1 marathon. Oh yeah, and the dog will be able to fit in the bow as well.

Solo. 18.5' long. About 23.5" at the water line with 200 pounds total weight (including the boat), about 27" at the widest and 21.5" at the gunwales if I remember correctly. Around 1.5" rocker in the bow and .75" in the stern depending on where you measure. I'm expecting low primary stability but pretty firm secondary. We'll see what happens.

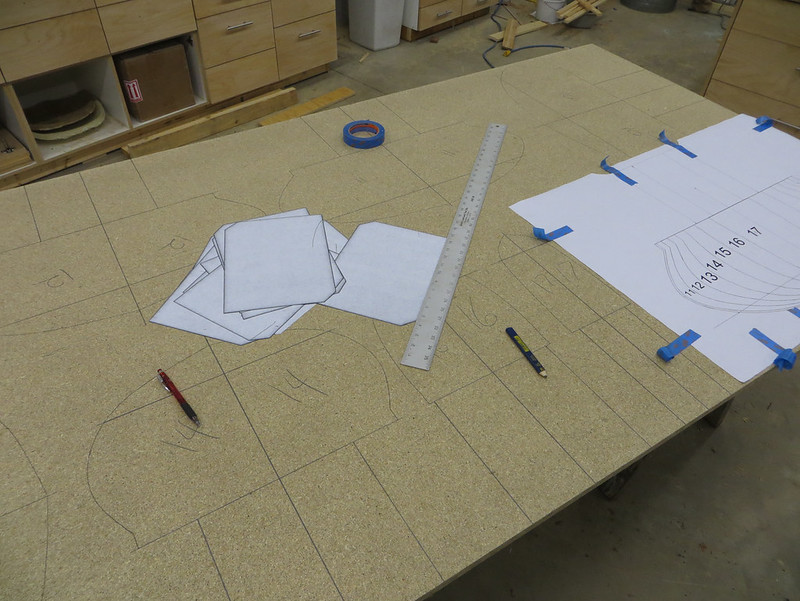

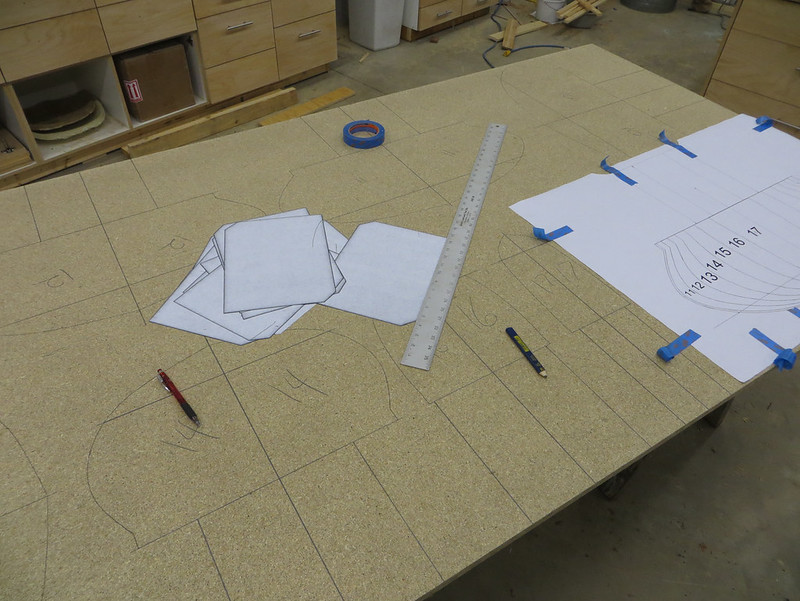

Got prints of the forms made last night and managed to get the stern sections transferred to particle board. Finished transferring the rest tonight and got the forms cut out on the bandsaw. Tomorrow I'll sand and hopefully get them on mounted to the strong back.

For the first time I used carbon paper for the transfer and I liked it. I thought it went pretty quick and the lines were nice and dark. I only traced the curvy lines. All the straight ones were just marked on each end and then joined with a straight edge after the paper came off. 8 1/2x11" was the biggest carbon paper I could find locally so I just used multiple sheets and it worked fine. Took a few sections to get a system down but after that all was good.

20141104_001 by Alan Gage, on Flickr

20141104_002 by Alan Gage, on Flickr

20141104_003 by Alan Gage, on Flickr

20141104_004 by Alan Gage, on Flickr

20141104_005 by Alan Gage, on Flickr

20141104_006 by Alan Gage, on Flickr

Alan

Solo. 18.5' long. About 23.5" at the water line with 200 pounds total weight (including the boat), about 27" at the widest and 21.5" at the gunwales if I remember correctly. Around 1.5" rocker in the bow and .75" in the stern depending on where you measure. I'm expecting low primary stability but pretty firm secondary. We'll see what happens.

Got prints of the forms made last night and managed to get the stern sections transferred to particle board. Finished transferring the rest tonight and got the forms cut out on the bandsaw. Tomorrow I'll sand and hopefully get them on mounted to the strong back.

For the first time I used carbon paper for the transfer and I liked it. I thought it went pretty quick and the lines were nice and dark. I only traced the curvy lines. All the straight ones were just marked on each end and then joined with a straight edge after the paper came off. 8 1/2x11" was the biggest carbon paper I could find locally so I just used multiple sheets and it worked fine. Took a few sections to get a system down but after that all was good.

20141104_001 by Alan Gage, on Flickr

20141104_002 by Alan Gage, on Flickr

20141104_003 by Alan Gage, on Flickr

20141104_004 by Alan Gage, on Flickr

20141104_005 by Alan Gage, on Flickr

20141104_006 by Alan Gage, on Flickr

Alan